Ocado, 2024

AI stock management that cut unfulfilled order items by 10%

AT THE TIME…

A rule set years ago was a rigid time window that didn’t give slower-moving stock or people a chance, causing waves of substitutions, shortages, and frustrated customers.

6-hour

unchangeable rule

when stock needs storing by

24%

of stock took longer than

6 hours to put away

Why not just automate stock timings?

Our data science did: they trained a machine learning model to predict putaway times based on historical operational behaviour. In simulation, this reduced substitutions and shortages by ~12%.

However, we realised the model didn’t account for future disruptions, so with the team, I introduced a tool that allowed managers to override predictions when needed.

People in a warehouse aisle, with products stocked to the left and order crates on the right, ready for packing items

SPEAKING WITH WAREHOUSE TEAMS

Critical putaway decisions are made as issues arise

I identified 2 main scenarios from users that guided my designs: to be able to store and sell short shelf-life products quickly, and to allow for longer putaway times for when unexpected disruptions occur.

When stock needs more time

Public holidays and weekends meant fewer staff available.

Bulkier and promotional products with larger packaging need extra time.

Freezers in the warehouse became inoperable.

When stock needs less time

Short-life products like sushi have a higher risk of going to waste and must be stored and sold quickly in the chilled part of the warehouse, well before the 6-hour mark.

When suppliers deliver late to the warehouse, teams strive to put things away quicker.

With all the prioritised scenarios I had, I asked the question…

How might we help warehouse teams combine machine-generated putaway predictions with real-time conditions so products are reliably available to customers?

BRAINSTORMING

How AI and people work together

I led my team to create UI concepts of how the machine learning model would work alongside a user override function.

We wanted the AI model to do most of the work, with users trusting the model when it's correct, and overriding it when they know better.

A user flow from the team workshop I led revealed the layers where services and people needed to interact

Making putaway planning bidirectional: by time or stock volume

Managers plan stock putaway daily, reacting to supplier deliveries as they arrive. This made it difficult to plan ahead with confidence, as throughput depended heavily on when stock landed.

To address this, we introduced a stock goal — allowing managers to plan by the percentage of stock they needed to put away, rather than relying on uncertain delivery timings.

Results of juicing the good parts of team sketches: a wireframe on what a UI solution for viewing, and overriding putaway times could look like

USER INSIGHT

Manual first, AI when we're ready

Presenting the concepts back to participants, I discovered that the 6-hour putaway time was a trusted anchor. One of our partners saw it as a crucial ‘line in the sand,’ giving them confidence amidst unknowns.

In response, my team scaled back the AI functionality for this partner specifically. I kept the 6-hour timing as a constant, but designed a clear override system, giving managers full control from the outset.

FOCUS AREAS

Managing putaway overrides in one place

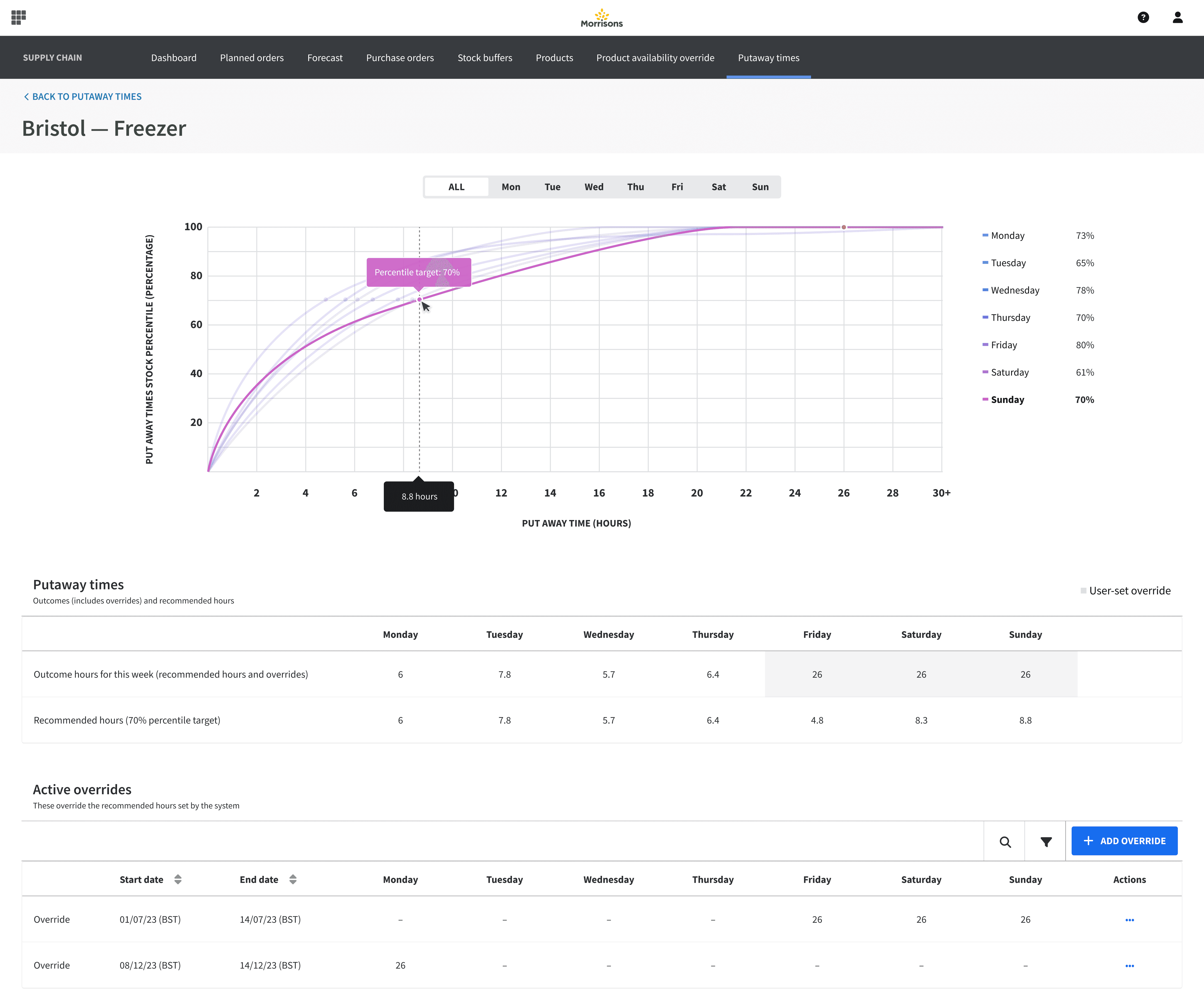

While the AI model provides recommendations, managers need clear, accessible tools to apply their judgement when real-world conditions change.

I designed a clear, centralised override system that allows managers to view, add, edit, and remove overrides in one place.

Putaway times showing a stock goal, and a user override in play

Adding a new override for a new week

Overriding in bulk

Legacy warehouses lacked higher-level putaway settings and planning relied on repetitive, low-level overrides.

I designed a bulk override workflow that removed this friction, making putaway planning faster and more consistent across these warehouses.

Error handling

As bulk overrides were handled in a CSV file and allowed for free input, this was prone to high validation errors. So, I designed clear error messages to surface the status of these uploads.

OUTCOME

Releasing a new application that gives managers confidence in putaway decisions

The new application gave managers clear visibility into putaway times at both product and storage-zone levels, allowing them to apply overrides with the right level of granularity.

Introducing a stock goal shifted planning from reactive estimates to a clear target, giving teams a tangible benchmark to plan toward and align on throughout the day.

REFLECTIONS

Our new tool, live in action in the USA! 🇺🇸

A month after we launched the application, my product manager visited the USA, where one of our partners, Kroger, adopted the feature. Their analyst tracked the impact, and since the trial period, we saw an average decrease of 100 unfulfilled items for customer orders per day — a 10% reduction!

Outdated rule removed. More customer items delivered.

Keep stakeholders close

There were A LOT of people involved and interested in the project. Noting down what level of involvement teams wanted and how they wanted to be informed helped me adapt my communication style for different members and give them the right level of information at the right time.

Speak up for good design

I was the sole designer on a highly data-driven team and I had to actively speak up for design under delivery pressure. I pushed for early user engagement and used those insights to shape decisions, ensuring the experience was grounded in real user needs, not just the data.